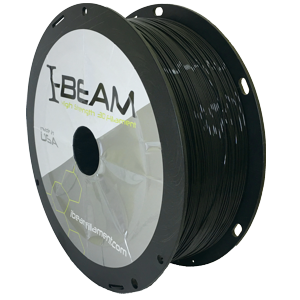

I-BEAM IMPACT Red PLA High Strength 3D Printer Filament – 1.75mm / 1kg Spool

I-BEAM IMPACT PLA was developed to be the strongest, easiest to print, most accurate, and most reliable PLA filament on the market today. Many PLA filaments tend to be brittle, but IMPACT PLA is a true high strength 3D printer filament. I-BEAM IMPACT PLA is based on a custom blend of Natureworks brand high temperature PLA using proprietary impact modifiers.

- Strong filament for making functional parts

- Near perfect overhangs and supported layers

- Annealable for even stronger parts and higher heat deflection temps

- 100% consistent and accurate results

- Very easy to print on any printer

- Bio-based using genuine NatureWorks PLA polymer

- Made in USA

$42.99

In stock

Material: I-BEAM IMPACT PLA

Actual Weight on Spool: 1000g

Approximate Length on Spool: 330m

Diameter Tolerance: ± 0.05 mm

Density: 1.24 g/cm3

Glass Transition Temperature: 55°C to 60°C

Suggested printing temperature: 210°C – 240°C‡

Suggested print speed: 35 – 100 mm/s

Cooling Fan: yes

Suggested heated bed temperature: 50°C – 60°C

Build platform

I-BEAM IMPACT PLA filament adheres well to both heated and non-heated build platforms. We recommend printing on BuildTak.

If printing on a glass bed, apply glue-stick. A very thin layer of glue will be sufficient to keep your print nicely in place. Another gluing method is dissolving PVA glue in water. The consistency of the mixture can be quite thin, like skim milk. By applying just a few drops and smearing the mixture out before you start printing will create a very thin layer which will hold the filament down.

‡3D printers use a variety of hot-end designs which makes it difficult for us to provide a universal temperature. Please refer to your printer’s operating manual for safety and temperature specifics.

In-house testing

All I-BEAM filaments have been rigorously tested at STACKER to ensure the best results possible. We not only test I-BEAM filament on our STACKER 3D printers, but we have also test I-BEAM on a variety of other 3D printers in our print lab to ensure quality and functionality of I-BEAM filaments. If you’re not sure how to print with I-BEAM, please contact us at info@stacker3d.com.

Low Carbon Footprint Bio Filament

IMPACT PLA filament uses bio-plastic from NatureWorks. Because I-BEAM IMPACT PLA is made from plants, it is essentially made from greenhouse gasses. As a result, PLA has a much lower carbon footprint than any other 3D printer filament. I-BEAM proudly uses a specialized formula of NatureWorks. Click here to learn more about Ingeo and greenhouse gasses.

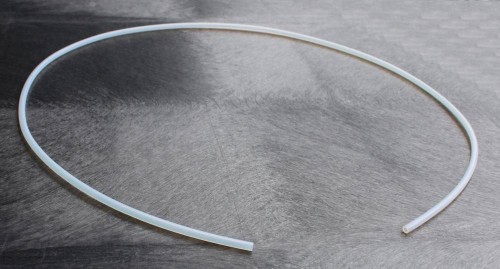

Excellent diameter tolerance

I-BEAM uses sophisticated and highly precise laser measuring systems to check the diameter of the filament in real time during the actual production process. It’s measured over 1000 times per second and this helps guarantee that each spool of filament is produced within tolerance. We can guarantee +/- 0.05mm for our 1.75mm diameter filament, which means you can be rest assured that your printer is extruding the exact amount of material called for.

Climate Controlled Warehouse

STACKER warehouses all of its filaments in a climate controlled warehouse to protect the filament from heat and moisture which can degrade the life and performance of some filaments.

Annealing I-BEAM IMPACT PLA

We recommend using a lab oven (although any oven will work). Set the temperature at approximately 120°C (250°F). Place your part on a baking sheet and place in the preheated oven. The annealing process takes approximately 20 minuets for smaller parts (larger parts may take up to an hour to fully anneal). Note, the part will shrink during the annealing process. After baking the part, remove from oven and allow to cool before handing the part.

Spool Size:

Outer Diameter: 200mm

Thickness: 73mm

Inner Diameter: 53mm

Tech Downloads: Technical data and MSDS sheets are available at http://i-beamfilament.com/Materials