HOW DOES IT WORK?

- Open the F-BOX and drop in your roll of filament. Feed the filament through the fitting and seal the lid with the four latches.

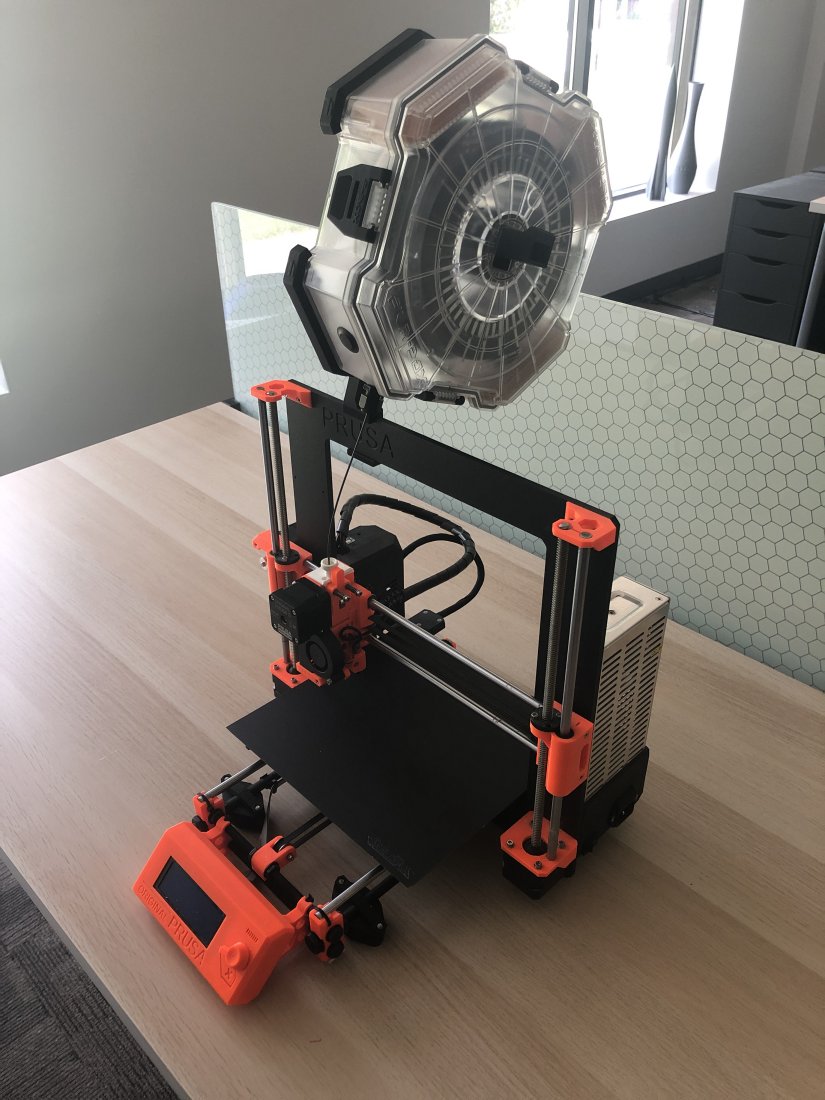

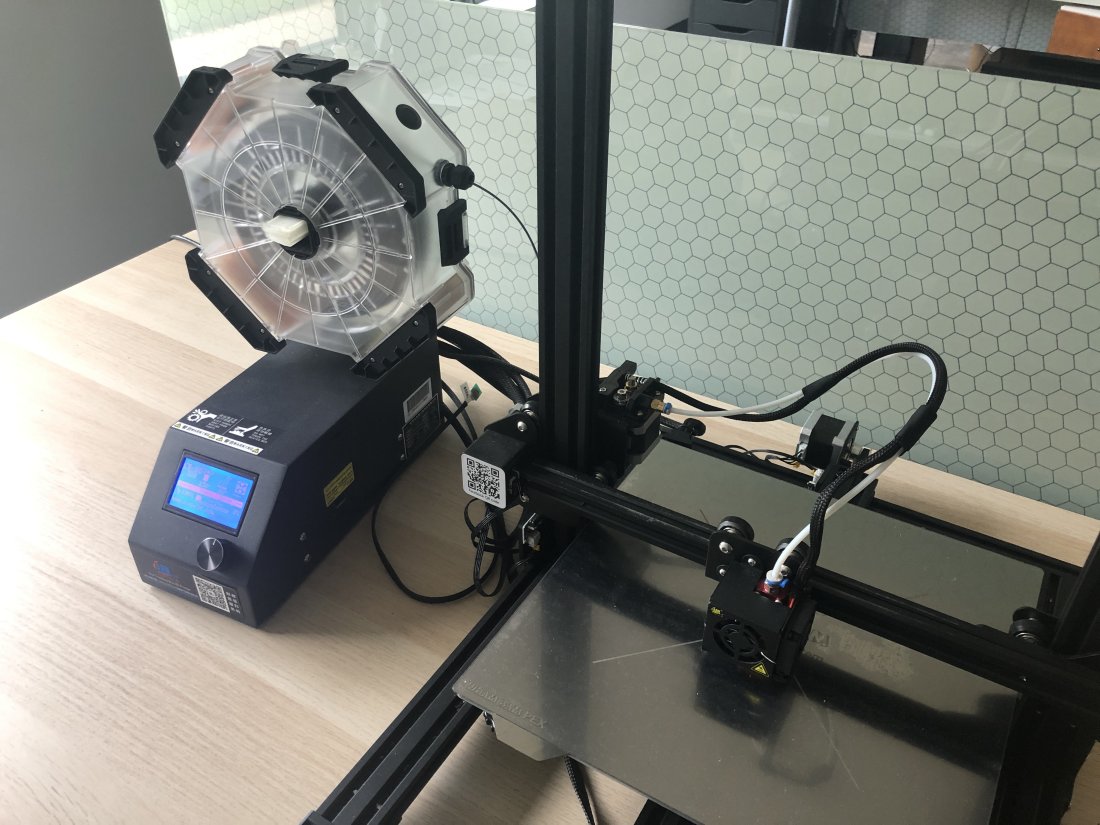

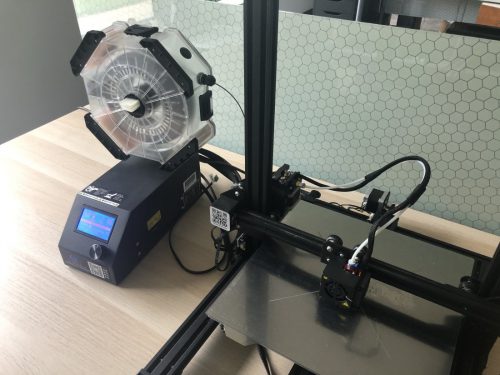

- Place the F-BOX on or near your printer and feed the filament into your filament drive.

- Print.

As you can see from the photos you can mount the F-BOX directly to your printer in various ways. We have designed a number of brackets for popular 3D printers.

The F-BOX uses high performance color changing desiccant to quickly absorb the moisture away from your filament. The F-BOX is air tight and is designed to reduce the interior air volume

WHY WE NEED TO USE DRY FILAMENT

Nobody likes ugly prints with a poor surface finish, so for this reason alone you should be drying your filament, but there are two more important reasons.

First, dry filament produces much stronger parts. You dry your filament to prevent polymer chain degradation, known as hydrolysis. Hydrolysis leads to really weak parts. The strength of your filament is derived from long chains of polymers. When humidity gets into your filament it acts like a knife, cutting up the long polymer chains into much shorter ones. Short chains lead to extremely weak parts.

Once your filament is dry you need to keep it this way at all times, before, during, and after the printing process is complete. In other words, drying your filament is good, but if you don’t dispense it from a dry box it will pick up new moisture in as little as 15 minutes. The F-BOX dries, stores, and dispenses from the same air tight box.

Also, don’t expect your filament to be dry from the factory. It’s not even close. Polyethylene bags are not impervious to air moisture. If you don’t believe me just put an onion in a bag, place in the fridge, and watch it shrivel up over time. It’s drying out because moisture slowly travels through plastic bags.

Second, wet filament leads to an increase in hot end jams. The reason is that moisture changes the melt viscosity of the polymer.With some polymers this may result in increased friction. In other polymers increased moisture may actually lead to less viscosity, but increased porosity and degradation of the polymer chains, primarily due to severe chain breakage. Really wet filament also generates steam, and this will quickly separate the base material.

What is it?

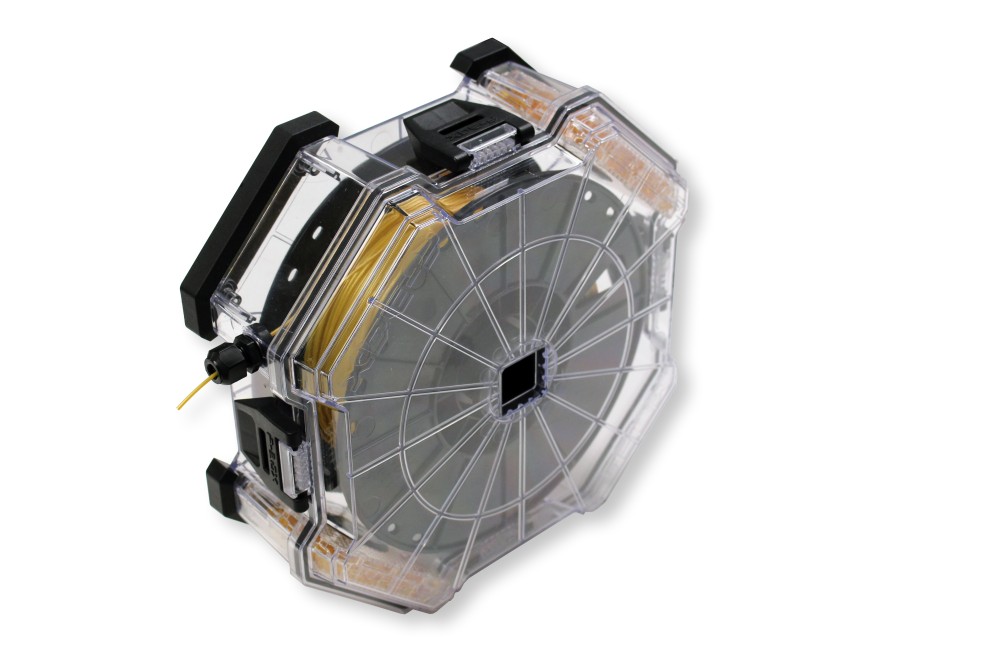

The F-BOX is a custom designed drybox for 3D printer filament.

What size spools does it fit?

It fits virtually EVERY spool on the market today. The F-BOX fits 1kg spools and smaller.

What does it do?

The F-Box dries, dispenses, and stores filament spooled on 1kg spools (or smaller).

Benefits

There are a lot of benefits to using the F-Box, not the least of which is achieving the best print quality and the strongest parts. It also ensures you get a great first layer bond to your build plate. The F-Box also keeps your filament clean and tangle free. The boxes stack and interlock making them the ultimate storage solution.

• Reduces jamming

• Dramatically improves print quality and layer bond strength

• Works with all filament, especially needed for PLA, PETG, PVA (and other soluble support materials), and Nylon polymers.

• Keeps your filament dry, clean, and safe

• Helps reduce filament overrides (tangles)

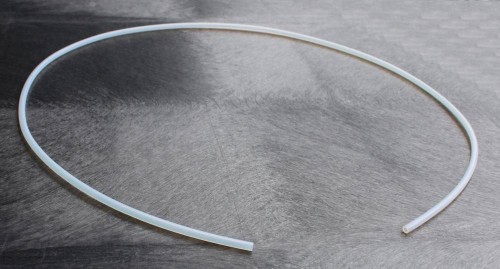

• Closed loop dispensing through supplied tube keeps filament dry once it leaves the box.

• Save filament and reduce the need for reprints

• Stackable design saves space

• Worry free printing

• Saves you time and money

• Prevents PLA filament from breaking before it’s even extruded, very common with wet filament.

Features

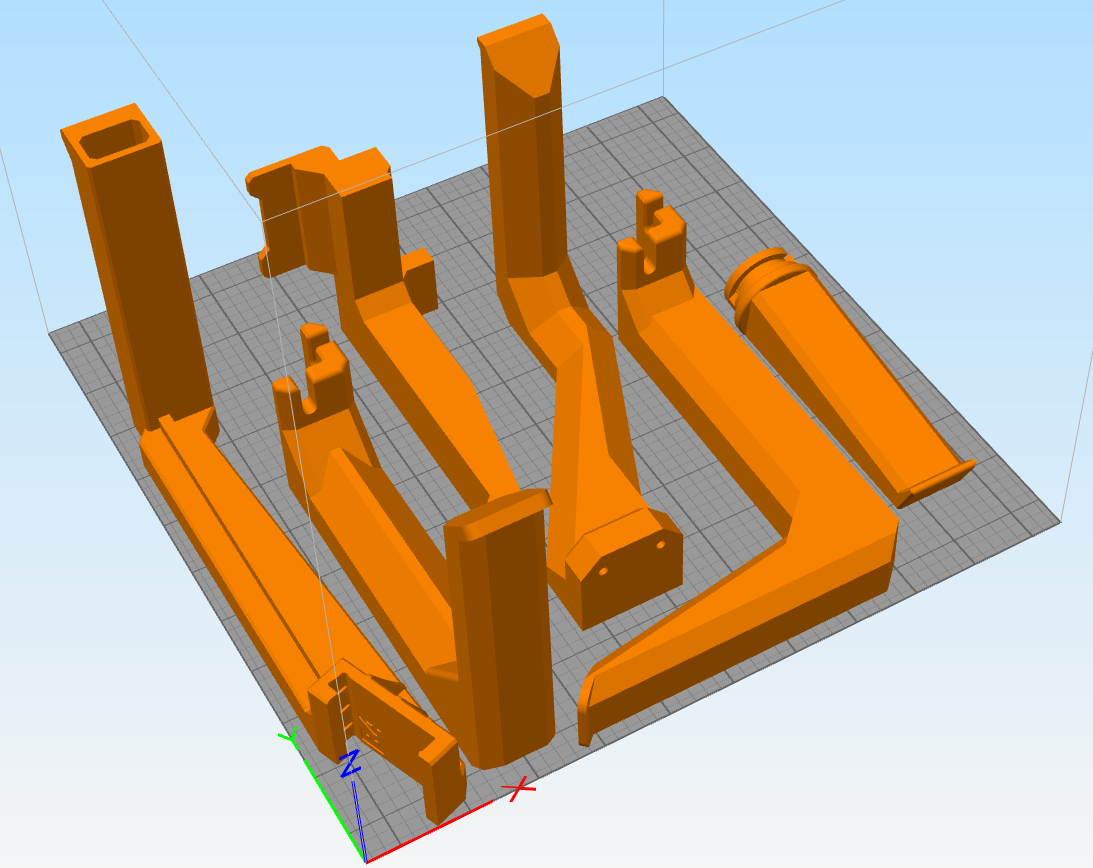

• Exclusive square thru hole allows you to mount the F-BOX directly to any 3D printer! (may require printing a new square post spool holder, STL files available on our website).

• Special seals keep out the moisture and dust.

• Four quick release latches ensure a tight seal

• Open lid design allows for fast filament spool changes

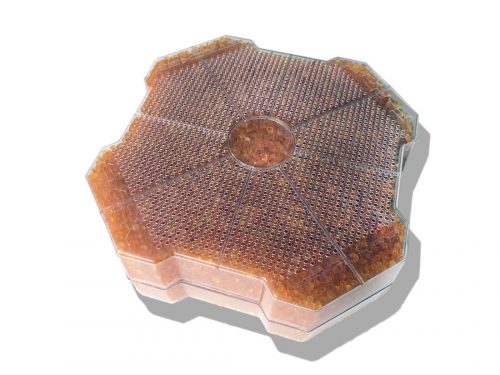

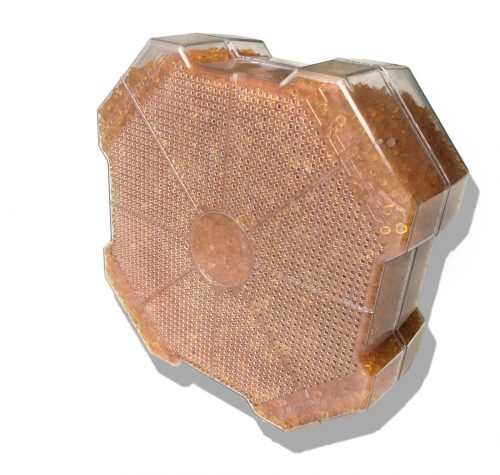

• High performance quick change desiccant cartridges.

• Color changing desiccant to let you know when a recharge is necessary

• See thru box design for easy identification of filament levels, color, type, etc

• Bowden tube fittings allow for closed loop dispensing and custom length tubes

• Stackable, nesting, interlocking design.

• Tightly sealed box to extend the life of your desiccant

• Recharge your desiccant over and over and over.

How do I recharge the desiccant packs?

Use a food dehydrator and set the temp to 65C (150F). Don’t use a higher temp than 65C. Set the timer for 3-12 hours or until the desiccant is bright orange. Using an oven or microwave will likely damage your desiccant packs. Order spare desiccant packs here.

The design

We spent months and months perfecting the design of the F-BOX. There’s a lot more to this product than meets the eye. Take the spool post, it snaps into the main housing and has two special seals to keep out the elements, while allowing your filament to effortlessly unspool. The lid has four latches to ensure a proper seal. The high quality fitting has dual o-rings to create a perfect seal. The feet allow the boxes to stack and nest.Finally, the exclusive square thru hole allows the F-BOX to be mounted directly on your printer.

FAQs

Q: Why do we need to dry our filament?

A: You dry your filament to prevent polymer chain degradation, known as hydrolysis.

Q: What are the effects of hydrolysis on filament?

A: The strength of your filament is derived from long chains of polymers. When humidity seeps into your filament it acts like a knife, cutting up the long polymer chains into shorter ones. Shorter chains produce much weaker parts.

Q: Can’t I just dry my filament in a food dehydrator and then use it right away?

A: Yes, but it’s not ideal. Most filaments pickup moisture in as little as 15 minutes. That’s why you need to dry and store your filament, preferably at the same time.

Q: Isn’t my filament dry from the factory? After all, it’s sealed in a bag with a small pack of desiccant.

A: Your filament is not even close to being dry from the factory unless the factory is located in a desert environment, which most are not. First off, polyethylene bags are not impervious to air moisture. Second, most filament is cooled on the extrusion line in a bath of water, and then it’s spooled immediately and sealed with a small pack of desiccant. In all likelihood your filament will be the same humidity as the outside humidity in your area by the time you receive it.

Q: Why don’t the makers of filament simply dry the filament correctly and then seal it in an airtight bag?

A: First off, this adds another step in the process, a lengthy and costly step at that. Second, the cost of truly airtight bags is just another expense most filament makers are unwilling to make. Besides, unless they thoroughly dry the filament first it’s not going to make a difference anyway.

Q: What should I do with my new roll of filament?

A: You should place it in your F-BOX with three recharged packs of our high performance desiccant. The F-BOX will dry the outer coils of filament, and you’ll be ready to start printing in minutes just so long as it's not fully saturated with moisture. If you're unclear, simply pre dry your filament in a dehydrator for a few hours.

Q: What should you do if you know your filament is saturated with water?

A: You should pre dry it in a food dehydrator because this will work faster than using desiccant.

Q: How do I recharge the desiccant packs?

A: Use a food dehydrator and set the temp to 65C (150F). Don't use a higher temp than 65C. Set the timer for 3-12 hours or until the desiccant is bright orange. Using an oven or microwave will likely damage your desiccant packs.

Q: How do I know if my desiccant needs to be recharged?

A: If your desiccant is bright orange it’s ready to be used. If it’s not bright orange you should immediately recharge.

Q: Can wet filament really cause hot end jams?

A: Absolutely. We have first hand experience with this problem. Dry filament rarely if ever clogs the nozzle.The reason is that moisture changes the melt viscosity of the polymer.With some polymers this may result in increased friction. In other polymers increased moisture may actually lead to less viscosity, but increased porosity and degradation of the polymer chains due to severe chain breakage. Moisture turning to steam can easily separate the base material, causing other problems.

Q: Will my prints tell me if my filament is wet?

A: The first thing you will notice is a poor surface finish, but not always. If the filament is really saturated you will see steam coming out of your nozzle along with the filament! Another good test is to see how brittle and weak your 3D printed parts are.

Q: How can I tell if my filament is wet before I print?

A: When PLA gets wet it becomes very brittle, and may break on the spool. Nylon, on the other hand, actually gets more flexible (and tough) when wet. Most other filaments will not give you any indications. Therefore, it’s really important to place your filament inside an F-BOX. If the desiccant is bright orange it’s likely your filament will be dry.

Q: Why do I need to anneal nylon, and what does this mean?

A: Nylons are a unique filament. On the one hand you need to dry the filament before you can print with it, and on the other hand these freshly printed parts will be very brittle until you anneal it, which simply means you introduce moisture into the finished parts. Keep in mind that wet nylon is still weaker than dry nylon. Dry nylons will usually be stiffer and stronger, but not as tough, or flexible as conditioned or wet nylon. If you need flexibility and toughness, anneal.

Q: Which filaments should be dried prior to use?

A: All popular filaments types like ABS, PETG, PLA, Polycarbonate, and Nylon are highly hygroscopic and must be dried. These resins act like sponges soaking up moisture from the air. Even non-hygroscopic filaments like polypropylene will develop surface moisture that can, in some rare cases, be a problem.

Q: Can I use a humidity detector (RH) to measure how wet my filament is?

A: Yes. As long as you measure your filament at room temperature, your RH readings will be very helpful.

Q: What is the ideal RH we’re trying to achieve?

A: IIn general, you want your filament to be as dry as it will go. In the F-BOX it’s easy to get the RH well below 10% at room temperature.Let’s assume your room temp is 22C and the RH inside your F-BOX is 5%. In this example the dew point is -19C. This is considered quite dry and will quickly remove the moisture from your filament. We have found that most filaments respond well to an RH of 15% or dryer. Keep in mind that humidity levels in the summer can easily reach an average of 40-60%, or higher, even in A/C or conditioned spaces. This is obviously too wet. However, even RH levels as low as 25% are still too wet for most filaments!

Q: What is dew point, and is this a better measurement than RH?

A: Dew point is the temperature at which the moisture in a gas will condense. More specifically, it is the temperature at which the vapor pressure of a gas equals the saturated vapor pressure. For our purposes, the gas in question is the air inside the F-BOX. The more parts per million of water particles in the air, the higher the vapor pressure, and consequently, the higher the dew point. As the dew point of air is reduced, its ability to take in moisture is increased.

The difference between dew point and relative humidity (RH) as a measurement of moisture in air is that relative humidity changes as the air temperature changes, but the dew point stays constant with temperature change. In other words, dew point is the measurement of actual water content. RH changes with temperature, even with the same amount of moisture in the air, because the density of air changes with temperature.

So, is RH or dew point a better measurement? Since most people use their 3D printers at or near room temperature the difference between the two is really just a number, and both work equally well for our purposes. It’s also easier to find inexpensive humidity meters that do a good job at accurately measuring RH. The RH number can then be calculated to find the dew point if that’s the measurement you prefer to work with. Dew points below 0 degrees will usually be sufficient to dry your filament. The lower the better.

Q: Does adding more desiccant packs to the F-BOX lower the moisture content of the air?

A: Yes. The more desiccant the more the air is in contact with it, and this lowers the dew point.

Q: Does adding heat to the air inside the F-BOX lower the dew point?

A: Yes, but it’s not absolutely necessary, except for regeneration of the desiccant.

Q: Does dirty and dusty air reduce the effectiveness of your desiccant?

A: Yes. It also reduces the strength of your 3D prints, and it also increases the chances of clogging your nozzles. The F-BOX is sealed, so you protect your filament AND your desiccant.

Q: Is desiccant hygroscopic?

A: Yes, it is very hygroscopic. This is the very reason we use it!

Q: What is your desiccant made of?

A: Our desiccant is high performance crystalline alumino-silicate molecular sieve.

Q: What is a molecular sieve?

A: It is a solid with a narrow uniform porosity which separates gas mixtures (air inside your F-BOX) by molecules of different sizes.

Q: Just because the air inside your F-BOX is super dry, does this mean the filament is also super dry?

A: Maybe. The filament on the inside of the spool may be less dry than the outside coils. The reason the F-BOX is so effective is that the filament is unwound at a pretty slow rate. This gives the exposed filament time to dry out before going into your hot end.

Q: If I already own a food dehydrator, should I stop using it?

A: Absolutely not! Keep using it, especially for saturated filament. The F-BOX will dry your filament at a slower rate than direct heat.

Q: What if I’m using more than one spool of filament at a time?

A: Just purchase more F-BOX’s.

Q: Is the desiccant toxic?

A: No.

Q: Does the F-BOX require assembly?

A: Yes, the F-BOX ships flat packed to make shipping less expensive and to better protect the components. Assembly is fast and easy.