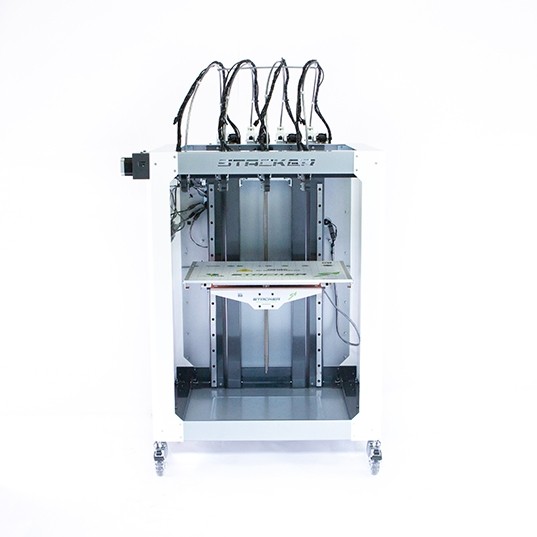

Stacker S4 Industrial Grade 3D Printer

NEW MODEL COMING JANUARY 2024!

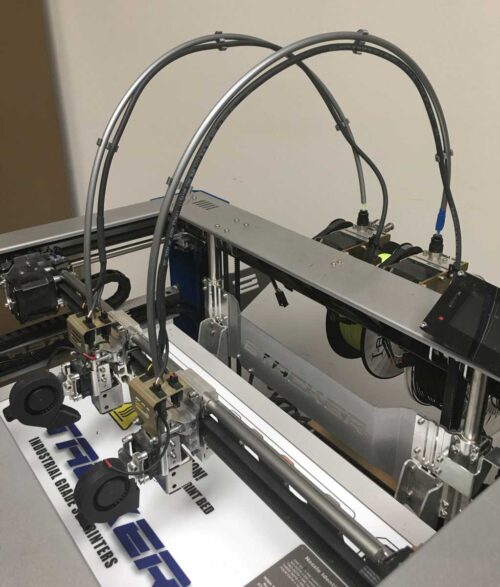

The Stacker S4 is a true industrial grade platform for 3D printing. You can print with up to four heads at once for faster production speeds. You can remove heads to utilize the entire build volume. You can have the heads work together for multi-material printing. From Prototype to Production™ the S4 has you covered.

View Print Samples

- Print up to four parts at once – 4x print speeds

- Group heads together for multi-material prints

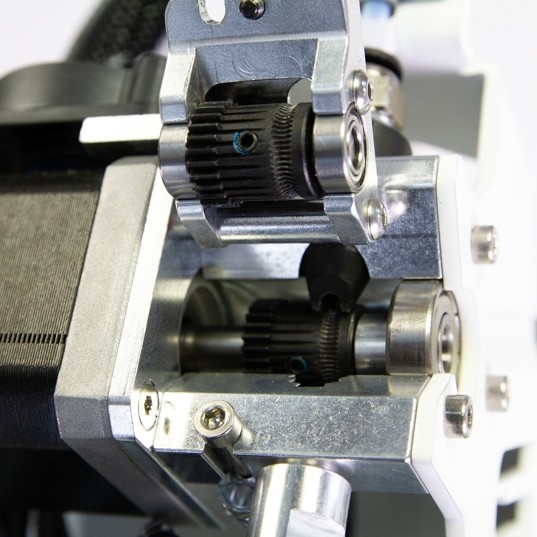

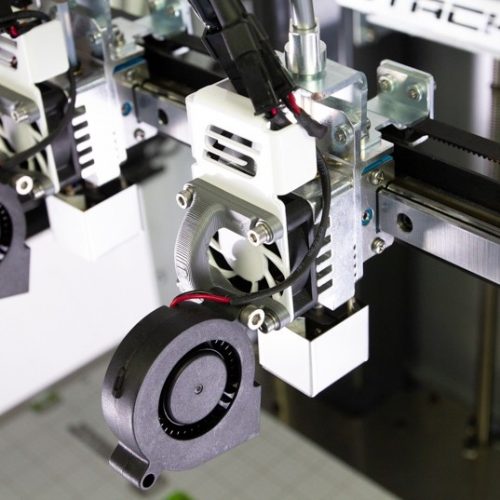

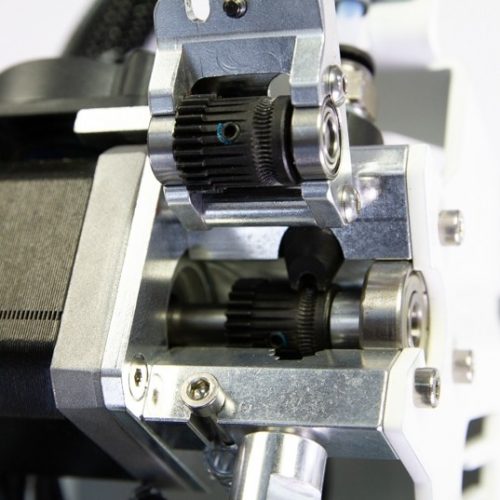

- Filament drives can be mounted in Bowden and Direct Drive configuration.

- Optimized for high tech composite filaments like carbon fiber (colorFabb XT-CF20)

- Nozzles offer fast reliable printing over wide range of materials

- Heated print bed

- Build area up to 345mm x 520mm

- Print parts up to 595mm tall (23½”)

- Integrated casters for mobile printing

- Safe to use in any environment

- Industrial duty components

- Made in USA

Print functional prototypes, production parts, jigs, fixtures, signage, movie props, architectural models, artwork, investment casting molds, and much more with high accuracy and repeatability.

Please contact sales@stacker3d.com for current lead times.

$12,999.00

Out of stock

STACKER S4

- 4X Faster Print Speeds. STACKER’s multi-part printing technology allows you to print up to four copies of the same part, at the same time, in different colors, and with various types of filament. Why print only one part when you can get two, three or four parts at the same time? With multi-part printing, it’s like having four 3D printers in one.

- Huge Build Volume. With a single head, the S4 can print parts up to 365mm x 510mm x 595mm. The build area is nearly 14″ x 20″ and 23.5″ tall!

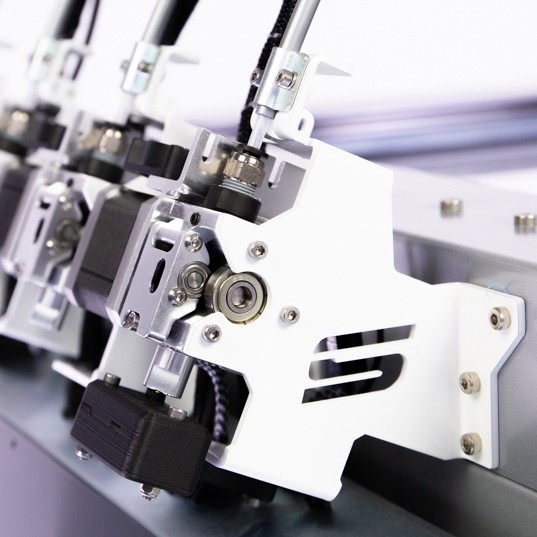

- Removable Print Heads. To maximize the build area, the S4 allows you to remove print heads easily.

- Universal Filament Rail. Our universal filament rail accepts any filament on the market. Unlike most commercial printers that gouge you with high priced materials, the S4 will accept market rate filaments, and this keeps your printing costs affordable. Our universal filament rail is designed for easy and fast loading of your filament spools. The “U” channel design fits all popular spool sizes. It is strong enough to easily support four 2.2kg spools of filament.

- Superior Positional Accuracy: S4 uses top quality linear motion components and a precision acme screw to achieve superior positional accuracy and repeatability.

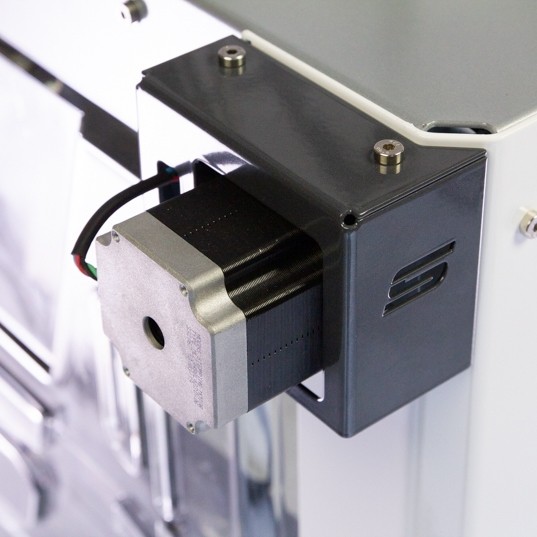

- Industrial Grade Motors and Drivers: Stepper motors and drivers are a key component in any 3D printer. STACKER only uses high quality stepper motors and drivers.

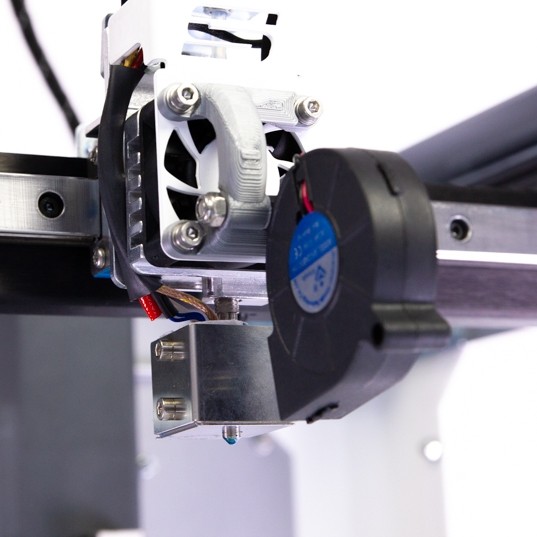

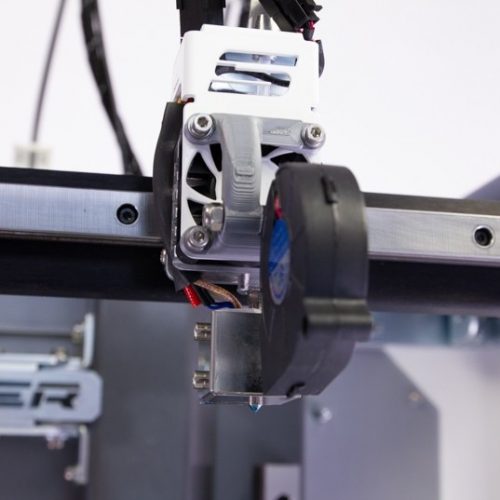

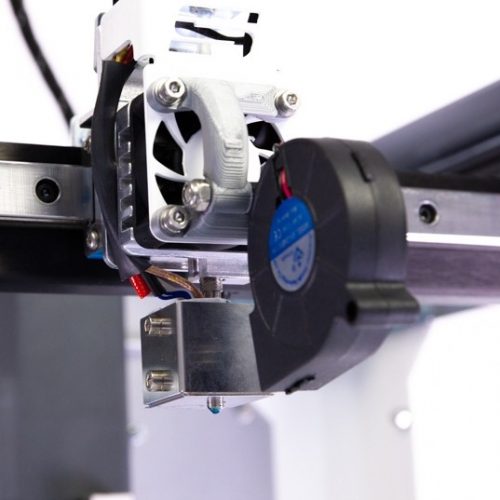

- Quick Change Nozzles: Changing your nozzle diameter is quick and easy on the S4. STACKER nozzles can be changed in less than a minute and come in a range of sizes from 0.25mm to 1.00mm. Moreover, our special grade stainless steel nozzles dramatically reduce wear and improve nozzle life when using composites like carbon fiber, copper, brass, or steel.

- Dual cooling fans. Our compact hot end design includes an integrated cooling fan for the heat sink and a powerful blower for cooling your filament while printing.

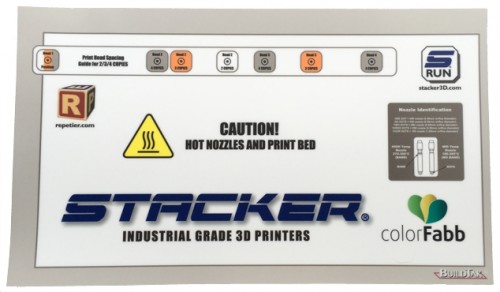

- Slicing software: Compatible with all popular slicers, like Simplify3D, CURA, Slic3r (including PrusaSlicer and SuperSlicer fork), Repetier (Slic3r and Cura engines), IdeaMaker, MatterControl, etc.

- Kinetic and Powerful Design. The S4 doesn’t look like a kitchen appliance because it’s not! STACKER is a productivity machine. There are no false bottoms or plastic panels to hide sloppy wiring and messy electronics. Everything is out in the open for easy accessibility. This makes it easy to modify your S4 machine to suit your exact needs. STACKER is perfect for use as a development platform or for alternative printing technologies.

A DIFFERENT KIND OF 3D PRINTER

STACKER offers a number of benefits over most other commercial 3D printers.

- S4 is affordable

- S4 can print four parts at one time, making it at least 4x faster than most other printers

- S4 accepts hundreds of different filaments in hundreds of colors, including our high tech composites, like carbon fiber

- S4 filament is market priced, not proprietary and overpriced

- S4 has a huge build volume (max print size is 345mm x 520mm x 5950mm)

- S4 has no service contracts

- S4 is highly mobile

- S4 fits into any workplace environment

STACKER was purposely built and priced for tech labs, colleges, busy offices, maker spaces, print/prototype shops, manufacturing plants, and most other kinds of businesses. Now, more professional creators have access to fast, reliable, and affordable 3D printing. From Prototype to Production™ the S4 has you covered.

What makes STACKER industrial grade?

STACKER stands above the rest by providing optimum chassis design, gantry, and high-quality components.

The Chassis

S4 relies upon high strength steel instead of plastic and composite frame parts. Our steel frame construction ensures your S4 will remain accurate for the life of your printer and far less susceptible to seasonal changes in humidity and accidental damage. It also means you can drill a hole into your machine and make other modifications without voiding the warranty or weakening the structural integrity. All of the components are powder coated for durability, and it makes your S4 look amazing!

STACKER 3D printers have a variety of nozzle sizes available. The speed you can print at with a small nozzle is much faster than the speed you can print at with a 1.00 mm nozzle, but don’t think your parts are going to get done faster just because you’re printing faster! It’s all about the volume of material you are laying down.

Here is formula:

(nozzle size) x (layer height) x (print speed) = cubic mm/sec.

So, with an 0.40mm nozzle, we take 0.40mm x 0.20mm x 150mm = 12 cubic mm/sec. If we take a larger 1mm nozzle, 1mm x 0.8 x 25mm we get a volume of 25 cubic mm/sec. As a result, you can see that a larger nozzle printing at a slower print speed will still extrude more cubic mm/sec than the smaller nozzle at a faster print speed. Larger nozzles can be a key to faster prints.

Printer Specs

- Type: FFF (Fused Filament Fabrication)

- Filament diameter: 1.75mm

- Hot end: HYBRID™ by STACKER

- Standard nozzle size: 0.40mm (Includes four 0.40mm Mid Temp nozzles)

- Option nozzle sizes: 0.25, 0.40, 0.50, 0.60, 0.80, and 1.00mm

- MAX Temp: 300° C

- MAX X/Y print area one print head printing: 345mm x 520mm (13.98″ x 20.67″)

- MAX X/Y print area two heads printing: 345mm x 240mm (13.98″ x 9.45″)

- MAX X/Y print area three heads printing: 345mm x 143.5mm (13.98″ x 5.56″)

- MAX X/Y print area four heads printing: 345mm x 96mm (13.98″ x 3.78″)

- MAX Z height print area: 595mm (23.5″)

- Layer resolution: 0.1mm to 1mm or 100 micron to 1000 microns

- Positional accuracy for X/Y: 6 microns or .00023″

- Positional accuracy for Z: 4 microns or .00015″

- Real world print accuracy: approximately four thousands (depends largely upon filament diameter)

- Print speed: 10 to 150mm/s

- Travel speed: 0 to 250mm/s

- Build plate: aluminum bed with Flex-Plate and BuildTak™

- Print bed: heated silicone mat, 575 WATT

- Internal Voltage: 24VDC/5VDC

- Connectivity: USB and SD card; Raspberry Pi can add CAT5 and wireless connectivity and control

- Power supply inputs: (1) 115/230VAC (nominal) 8.5A

- Operating temperature range: 50-100°F (10-38°C)

- Operating Noise: 35 to 60 dB

Printing Modes

- STACKER has three print modes: Single-part, Multi-part, and Multi-material

- Single-part Mode: Use one print head to print one part. Basic one-off printing — load it, print it.

- Multi-part Mode: Print multiple copies of the SAME EXACT part. You can choose if you want to print two copies, three copies, or four copies of your part. Each head will performs the exact same movements producing exact copies of whatever head one produces. Because each hot end temperature can be independently adjusted, it is possible to print with different types of filament at one time!

- Multi-material Mode: Print one part with more than one material type. This mode allows you to extrude different materials from more than one hot end onto the same part. Just to be clear, you can only print one part at a time in multi-material mode. Because each hot end temperature can be independently adjusted. you can print a single object with different materials. For example, you could print the main part with head number 1 and print all of the support structure for that part with head number 2.

Physical Printer Specs

- Width: 720mm (28.3″)

- Height: 1100mm (43.3″)

- Depth: 900mm (35.4″) (with filament rail and 1kg roll of filament)

- Weight: 68kg (150lbs) (bare machine with no filament)

Shipping Crate Specs

- Crate is Heat Treated (ISPM 15 compliant)

- Length: 876mm (33″)

- Width: 762mm (33″)

- Height: 1382mm (54.5″)

- Weight: 154kg (340lbs)

Software Specs

- Included Software: STACKER RUN (our custom version of Repetier Host)

- Recommended Software for Raspberry Pi users: Repetier Server

- Supported file types: STL, OBJ, AMF

CE Certification

USER GUIDE

- S4 Support Page

The information below reflects shipping weight and dimensions (if applicable)

| Weight | 350 lbs |

|---|---|

| Dimensions | 34 × 35 × 52 in |