3D Printer BuildTak FlexPlate System for Stacker S4-XL

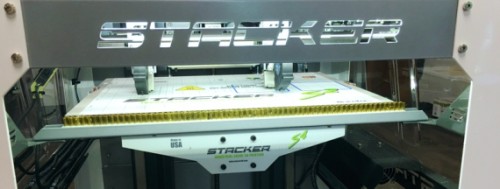

The BuildTak™ FlexPlate System for the Stacker S4-XL provides easy removal of your 3D printed parts. No more gouging of your BuildTak™ or breaking parts while trying to pry them from your print bed. With the FlexPlate System, your parts will literally ‘pop’ off when you bend the FlexPlate.

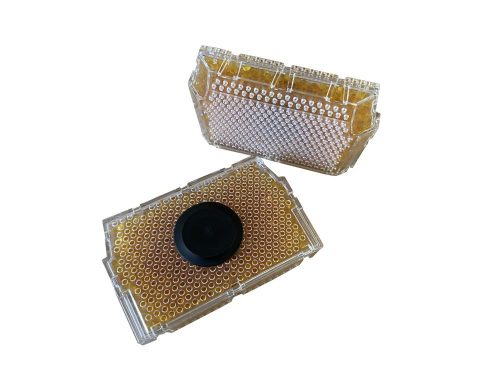

The FlexPlate System includes the metal BuildTak™ FlexPlate a sheet of our custom STACKER BuildTak printing surface, and a unique magnetic mounting base. The magnetic mounting base affixes permanently to your S4-XL glass bed. The magnets hold the metal FlexPlate in place during printing, and when the job is complete, simply remove the entire FlexPlate and flex it to remove your 3D printed parts.

Made in USA.

$499.99

In stock

The FlexPlate System is comprised of three components: (1) a metal BuildTak™ FlexPlate, (2) a sheet of our custom BuildTak printing surface for the FlexPlate, and (3) a unique magnetic mounting base. On the S4-XL, the magnetic mounting base affixes permanently to your glass bed; we recommend attaching the FlexPlate Base to the glass bed rather than the aluminum bed because the glass bed provides the flattest surface possible. Once the magnetic Base is attached to the glass bed, the magnets hold the metal FlexPlate in place during printing, and when the job is complete, simply remove the entire FlexPlate to ‘pop’ your 3D printed parts from the FlexPlate.

Note, the FlexPlate system will reduce the maximum achievable temperature of your print bed by about 10°C.

When printing production parts, use a second FlexPlate to reduce time between prints. Simply swap FlexPlates and start printing while you allow your freshly printed parts to cool.

Please visit the BuildTak™ Support Page for an instructional video and FAQ.

Related products

Spare Parts

S2 Accessories

Accessories

S4 Accessories (pre-SuperBoard)

500 Accessories

Spare Parts

Accessories

Spare Parts